Projects

</ Nutrition App >

The app aims to be an nutrition app designed to function as a personalized digital nutritionist. Meals can be logged through multiple methods, including manual entry, voice input, and camera-based recognition, creating a seamless and intuitive tracking experience.

Unlike generic diet apps, personalized nutrition plans are generated based on individual goals, preferences, and dietary needs. By analyzing detailed nutritional data over time, the system provides precise daily and long-term recommendations that continuously adapt as eating habits evolve.

The result is a data-driven, user-centered health solution focused on sustainable and personalized dietary improvement.

The AI functionality is built around custom-designed agents that combine large language models with structured data validation using Pydantic. This ensures reliable, well-defined outputs rather than unpredictable free-form responses.

Where mathematical precision is critical, custom optimization functions are used to handle calculations with high accuracy. This hybrid architecture blends data-driven AI reasoning with traditional analytical methods, creating a system that is both intelligent and mathematically reliable.

The result is a coherent and responsible automation layer capable of generating personalized diet plans and making context-aware nutritional recommendations with precision.

The frontend is built with Flutter, enabling efficient cross-platform deployment on both iOS and Android while maintaining a streamlined development workflow. Native functionality is integrated where needed, leveraging Swift and Kotlin to support platform-specific features such as Apple Health connectivity.

On the backend, a PostgreSQL database manages both user data and an extensive nutritional dataset containing millions of food items sourced from multiple government agencies.

To enable intelligent reasoning over this structured data, the AI agents access the database through a Retrieval-Augmented Generation (RAG) pipeline. This architecture allows the system to combine large-scale nutritional data with contextual AI reasoning, ensuring accurate, data-grounded recommendations.

</ audio interface >

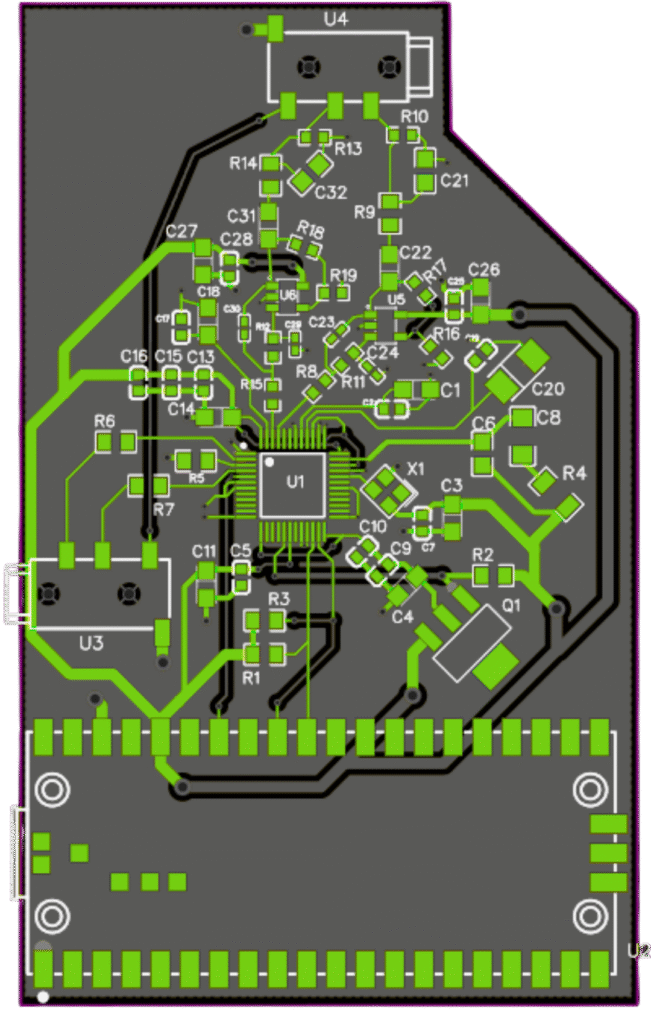

The goal of the project was to develop a device that can digitally process analog audio signals using an audio processor chip. This would make it possible, for example, to use old radios with modern sound enhancement features like equalizers (EQ) and noise reduction. The user could adjust the sound quality by boosting bass, reducing treble, or removing background noise.

At the core of the device is the ADAU1701, one of the many programmable audio processors made by Analog Devices.

Audio signals are fed into the device via an AUX cable. The chip’s ADCs convert the signals into digital form at up to a 192 kHz sampling rate, allowing for flexible signal processing.

Once processed, the signals are converted back to analog using DACs and sent to the output through the AUX connector. The system is supported by all necessary peripheral components of the chip, such as the crystal oscillator and operational amplifiers.

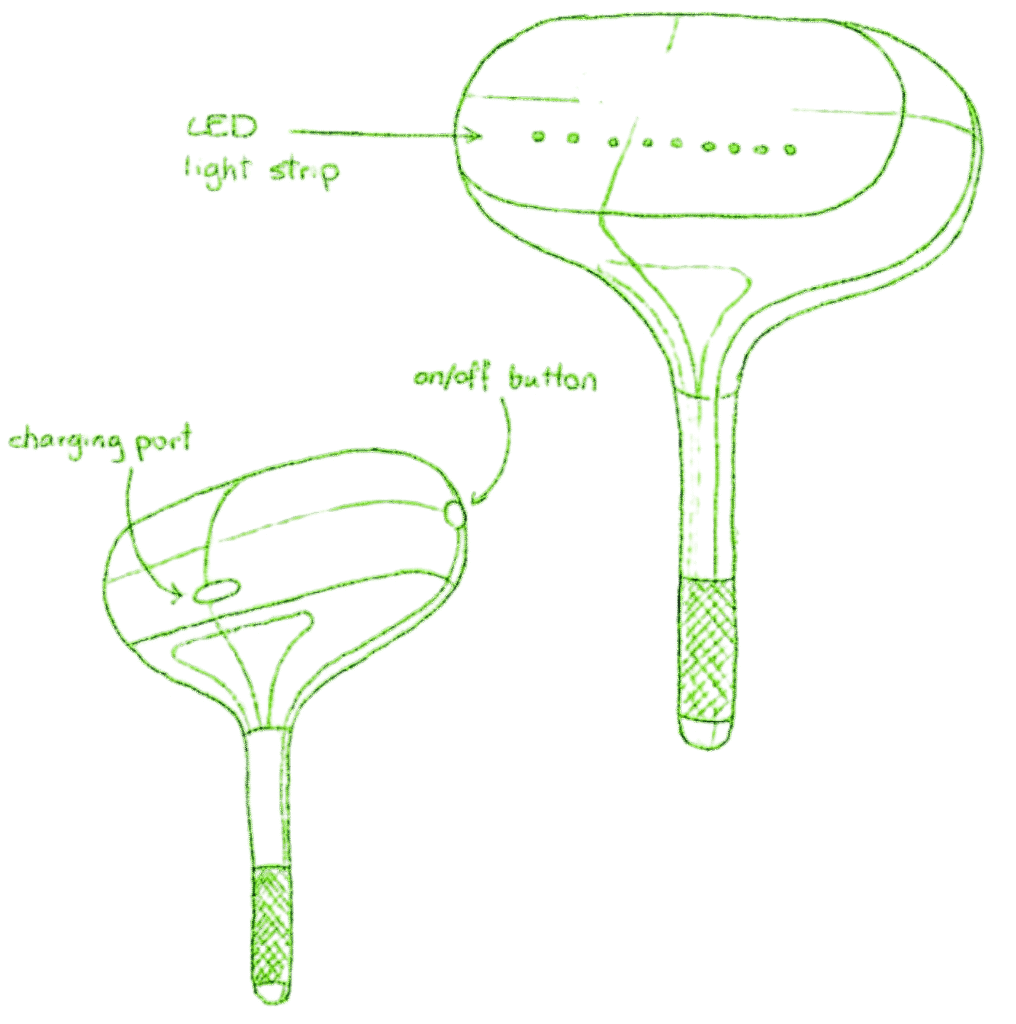

</ Smart lawn monitor >

The goal of the project was to develop a device that can be placed on a lawn to collect data about soil condition. The device measures factors such as moisture levels, nutrient content, and pH value, providing insight into the health of the lawn.

The idea is to help dedicated gardening enthusiasts take better care of their lawn, keeping it greener than the neighbor’s.

The device’s probe includes an integrated moisture sensor, NPK sensor, and pH meter to analyze the condition of the soil. The collected data is sent to an ESP32 microcontroller, which processes the information and transmits it to the user’s phone for real-time monitoring.

The project reached the rough prototype stage, resulting in a basic working device capable of sending the necessary data to a server via Wi-Fi. While the hardware and functionality were kept minimal, the core features were successfully demonstrated.

</ E-bike conversion kit >

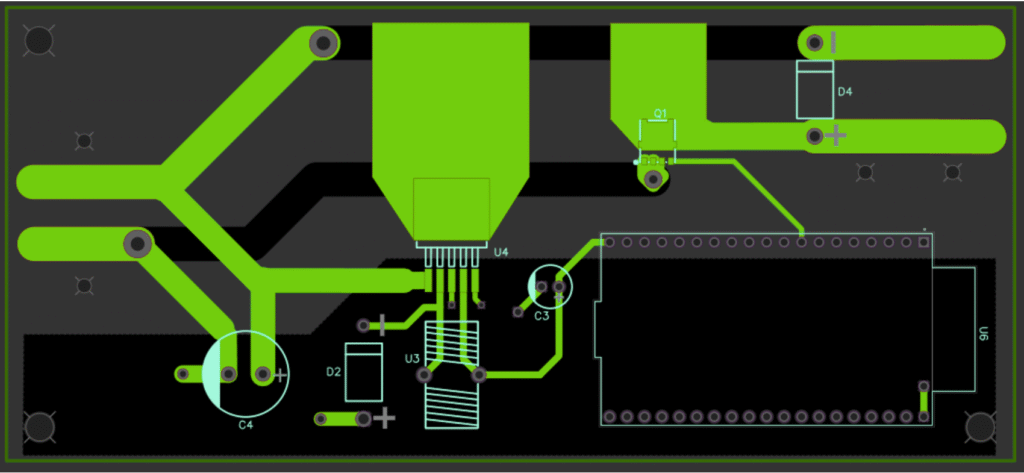

The project aimed to develop an easy-to-install conversion kit that transforms a regular bicycle into an electric bike without making permanent modifications to the frame. The solution utilizes the bike’s existing mounting points, eliminating the need to weld, drill the frame, or replace the bottom bracket.

At the heart of the system is a motor mounted onto the rear wheel, positioned over or in place of the hydraulic brake pistons. The motor drives a gear mechanism located between the rear hub and the brake disc.

The conversion kit also includes a thumb throttle operating with a Hall sensor and permanent magnet, as well as a battery.

The system is controlled by two microcontrollers, each with a clear role. The first microcontroller monitors the thumb throttle’s movements and sends the data both to the motor controller microcontroller and to the user via Bluetooth. The motor controller microcontroller regulates the current flowing through the 24V DC motor by generating PWM signals that drive an NMOS transistor